474 - Knowledge is the Key to a Successful Harvest

Preparation is a key item in a successful sugarbeet harvest. Inspecting and repairing your equipment prior to startup is a necessity. Having well trained crews takes training and effort, but in the long run it is some of the best time invested. Making small changes hour by hour and field to field will maximize returns. These are just a few of the basic building blocks of a successful sugarbeet harvest. Utilizing these strategies will make the 2005 harvest run much smoother and be much more profitable.

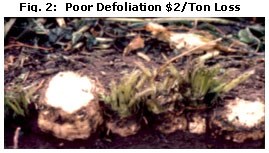

Defoliation - Slow Down For More Profit

Preparing the defoliator mechanically for the season is typically a fairly simple, but necessary task. Worn flails have reduced surface area on the face of the flail. Worn pivot areas allow flails to move left and right missing the target and leaving greens on the beets. Scalpers should be adjusted uniformly and sharpened prior to harvest.

Speed is the single most important factor when adjusting a defoliator. Keeping speed between 2 and 3 mph is critical. Defoliator operators should be hired for each shift and focus only on defoliation. Train them to inspect and replace flails, sharpen and adjust scalpers and instruct them on staying close to the harvester in heat and frost situations. The $1.79/ton revenue increase at 3 vs. 4 mph is not something you would be able to look at the beets and easily identify the loss. It is still a real loss of $35.80 per acre on a 20 ton crop. Remember with Defoliation "Speed Kills - Save the pocket book". Figure 1.

Revenue based on 2003 American Crystal Sugar Company final gross payment

Defoliation Keys

- Hire a full time defoliator operator

- Use defoliation speeds of 2 to 3 mph

- Replace worn flails

- Inspect equipment every shift

- Speed kills - save the pocket book

Harvester Speed and Depth Critical

Speed and Depth are the most critical settings to be adjusted in every field. Visual observation and harvest tools like the slide rule will guide you to make the right changes. Properly setting lifter struts is critical before adjusting speed and depth. Harvester speeds of 3 to 4 mph have resulted in the best revenue and lowest tare. American Crystal Sugar Company recommends digging depths of 2 ½" to 3" to achieve the best revenue and lowest tare. Well adjusted lifter wheels and struts are keys to a successful harvest. These adjustments determine how effectively the harvester will work. As you narrow up pinch points you are able to dig shallower reducing amounts of excess soil the rest of the harvester has to remove (charts below).

Total Soil in Lifted Area (Tons/Acre)

| Digging Depth | Pinch Point | Wheel Cut (2" wider) | ||||

|---|---|---|---|---|---|---|

| 1 1/2 | 1 3/4 | 2 | 3 1/2 | 3 3/4 | 4 | |

| 1 1/2 | 9.3 | 10.5 | 11.6 | 18.7 | 19.9 | 21.0 |

| 2 | 13.4 | 14.9 | 16.5 | 25.9 | 27.5 | 29.0 |

| 2 1/2 | 17.9 | 19.9 | 21.9 | 33.6 | 35.6 | 37.5 |

| 3 | 23.0 | 25.4 | 27.7 | 41.8 | 44.2 | 46.5 |

| 3 1/2 | 28.6 | 31.3 | 34.1 | 50.5 | 53.3 | 56.0 |

| 4 | 34.6 | 37.8 | 40.9 | 59.7 | 62.8 | 66.0 |

| 4 1/2 | 41.2 | 44.7 | 48.2 | 69.4 | 72.9 | 76.4 |

| Difference | 15.7 ton | 18.8 ton | 21.9 ton | |||

Canopy can be misleading - Weigh some beets from your fields to see what setting is right for you

Important Harvester Tips

- Harvester speeds of 3 to 4 mph

- Digging depth of 2 1/2" to 3"

- Pinch points of 1 ¾" to 1 7/8"

- Use harvester checklist before starting harvest

- Keep harvester slide rule in the tractor

Harvest Clinics

Agriculturists will be offering harvest clinics in many piling districts this year. Attend one if offered in your area.

Contact your Agriculturist for assistance with harvesting decisions.